Aviation Analysis Program

SEM

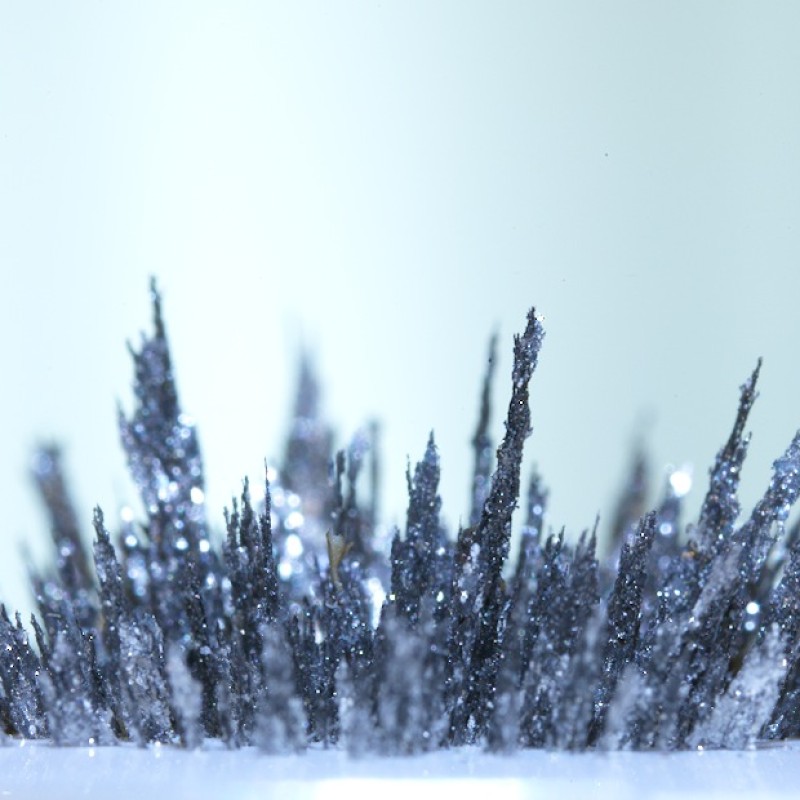

Debris to be analysed is placed in the SEM and bombarded with electrons which release X rays characteristic of the element that they hit. These X-rays are used to determine the elemental composition of the alloy. Our laboratory has always appreciated the analytical capabilities of a Scanning Electron Microscope (SEM) for the examination of metallic and non-metallic debris recovered from oil samples, oil filters, or chip detectors. A visual assessment of the size, shape and age (i.e. corrosion) of the debris forms the initial stage of analysis. Further investigations are conducted with the use of X-ray energy dispersive spectroscopy to determine the composition of the debris. For metallic debris, the material classification can be achieved by comparing these elemental results with published specifications. This can help pinpoint the source of the components responsible for the debris.

BACK